Materials testing and qualification

Materials testing – including corrosion and assurance testing – to regulatory standards and company requirements

Materials testing

DNV has specialized materials laboratories located in Norway (Oslo and Bergen), UK (Loughborough), Singapore and the US (Columbus, OH).

Some of our specialities are:

- Advanced fatigue and fracture mechanics testing

- Testing in realistic corrosion environments

- Qualification of composites, rubber materials and fibre ropes

- Qualification testing of coatings

- Mechanical testing.

Value added through tests we do

The quality of materials is crucial to the quality of products and the safety of systems.

Whether you run a production facility, operate complex technical equipment or supply raw materials efficient and reliable materials testing and qualification improves safety and technical performance, and reduces risks and costs. Defining the appropriate method of materials testing requires expertise in both materials and systems.

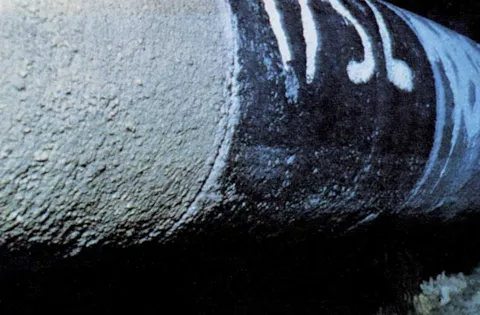

The aim of corrosion testing is to understand resistance to degradation by corrosion mechanisms or hydrogen-induced stress cracking (HISC), and to select appropriate actions to reduce the risk of failure. We carry out qualification testing to meet requirements, to sour service, coatings, anode testing and others, and run specific materials test setups to simulate operational environments, including corrosion in seawater, microbiological influenced corrosion (MIC), and stress corrosion cracking.

Our materials testing laboratories contribute to quality assurance during production by carrying out a broad range of destructive and non-destructive testing (NDT) using the latest technical equipment.

Areas where we combine testing and system knowledge

Our customers cover the entire oil and gas value chain, and we also serve other industries such as maritime, renewables and automotive.

A materials testing and qualification will typically verify material properties according to a specification, code or standard or as part of a customized fitness for service assessment.

Materials testing by DNV labs - what we offer:

- Rapid, reliable and certified results from an independent authority

- Transportation of samples

- High-precision materials testing

- Rapid workflows, smooth processing and minimal waiting periods

- Corrosion testing, including testing for stress corrosion cracking

- Soft seal testing

- Fracture mechanical testing

- Fatigue testing

- Coating testing

- Sour service testing

- Accredited labs (DIN EN ISO 17025)

- Material certificates in compliance with DIN EN 10204

- Chemical composition

- Mechanical properties (yield strength, tensile strength, toughness, hardness)

- Metallographic analysis (microstructure, grain size, heat treatment).

Laboratories providing materials testing and qualification

Related articles

Choosing the best materials to avoid environmentally assisted cracking

Expert advice before the design stage draws on testing and modelling to help specify the right materials for oil and gas equipment.

Three ways to overcome materials challenges in sour service fields

Improving asset reliability when faced with complex materials and integrity challenges in sour service field developments.

Preventing external corrosion failures

External corrosion is a threat to most equipment in every process facility and deserves closer analysis and prediction than it currently receives.

What causes materials failure in oil & gas and maritime equipment?

Systematic and thorough analysis is required to say with confidence what kind of failure is involved and what led to it

Tubes and piping are the most failure-prone components

In a study of 1,000+ cases in oil & gas and maritime, research by DNV’s laboratories also identify fatigue and corrosion to be the most common modes of component failure.